Crucial Variables to Think About for Elevator Maintenance

When it comes to the reliable and risk-free operation of lifts, taking into consideration vital maintenance factors is paramount. It is imperative for constructing managers and upkeep workers to stay in advance of these elements to maintain the elevator's performance criteria and compliance requirements.

Regular Assessment Schedules

Conducting regular inspections not only boosts the total efficiency of the lift yet also plays a crucial function in abiding by safety and security laws and industry standards. It ensures that the lift runs efficiently, decreasing the danger of unforeseen breakdowns that might aggravation occupants or concession security. Additionally, routine assessments add to prolonging the lifespan of the lift devices, inevitably lowering upkeep expenses and downtime.

To enhance the evaluation process, lots of building proprietors partner with qualified lift upkeep firms that specialize in carrying out extensive evaluations and giving timely upkeep solutions. By prioritizing regular examination schedules, stakeholders can copyright the safety and security, dependability, and efficiency of their lift systems.

Proper Lubrication Strategies

Effective lubrication methods are necessary for keeping the ideal efficiency and long life of elevator elements. Appropriate lubrication methods play an essential function in avoiding deterioration on relocating components, minimizing rubbing, and making sure smooth procedure of the elevator system. When it comes to elevator upkeep, making use of the appropriate lubricating substances in the proper amounts at the suggested periods is vital to minimizing and avoiding expensive repair services downtime.

To guarantee proper lubrication, elevator specialists have to follow manufacturer standards regarding the kind of lube to be used for specific parts such as bearings, gears, and guide rails - lift maintenance london. Over-lubrication can bring in dirt and particles, bring about element malfunctions, while under-lubrication can trigger boosted friction and premature wear. Regularly scheduled lubrication maintenance need to be included in the general elevator upkeep strategy to keep the system running efficiently and securely

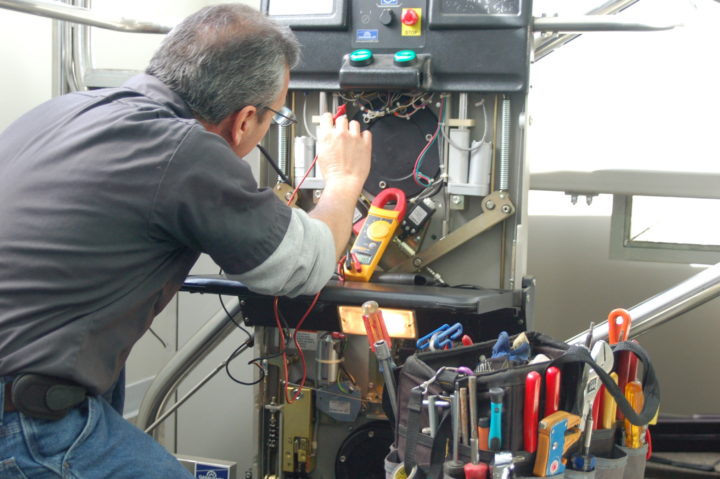

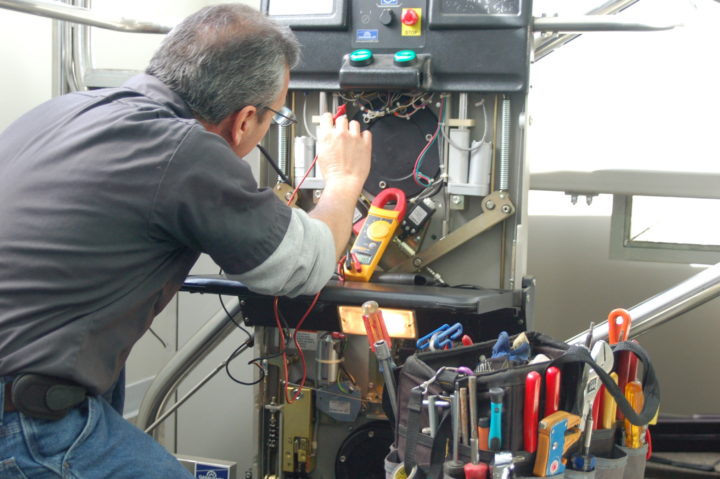

Keeping Track Of Damage

Proper lubrication techniques are indispensable in assisting in the very early detection and surveillance of damage on lift components. Regular lubrication assists reduce rubbing in between relocating components, stopping extreme wear and potential break downs. However, checking wear and tear surpasses just lubrication. Elevator anchor upkeep personnel need to carry out routine evaluations to determine indicators of endure crucial components such as ropes, sheaves, overview rails, and bearings. These evaluations may include aesthetic checks, measuring wear restrictions, and utilizing diagnostic tools to examine the problem of crucial parts. In addition, keeping thorough maintenance documents can assist in tracking the wear patterns of lift elements gradually, enabling predictive upkeep preparation. By very closely monitoring damage, upkeep teams can resolve issues proactively prior to they intensify into pricey repairs or unexpected downtime, making certain the effective and secure procedure of the lift system.

Safety And Security Conformity Checks

Carrying out extensive safety conformity checks is important in making sure the lift system satisfies all governing criteria and operational needs. These checks also entail validating that the elevator's capacity limitations, speed, and emergency communication systems are in line with safety and security requirements. Furthermore, adherence to safety and security compliance checks can stop accidents, decrease responsibility threats for building owners, and prolong Read Full Article the life expectancy of the lift system.

Emergency Action Planning

Because of the vital value of safety and security compliance sign in keeping lift systems, a robust emergency action preparation strategy is vital to quickly and successfully address unforeseen events. lift engineer course. Emergency situation feedback preparation for lifts entails aggressive procedures to make sure the safety of guests and maintenance personnel in the occasion of emergencies such as power outages, entrapments, or mechanical failures

Key components of an effective emergency reaction strategy consist of developing clear communication methods, supplying regular training to staff on emergency situation treatments, keeping current emergency contact lists, and conducting regular drills to exercise action actions. Additionally, it is necessary to have actually designated personnel responsible for working with emergency situation responses and ensuring that needed devices, such as emergency illumination and interaction devices, remain in functioning order.

Final Thought

To conclude, it is vital to prioritize regular evaluation timetables, appropriate lubrication strategies, keeping an eye on wear and tear, safety and security compliance checks, and emergency response preparation for elevator upkeep. By implementing these necessary elements, structure owners can ensure the safety and performance of their elevators, ultimately lowering the danger of breakdowns and accidents. Regular maintenance techniques are essential for lengthening the lifespan of lifts and making certain the well-being of individuals that count on them for transport.

Regularly arranged lubrication upkeep need to be included in the total elevator upkeep plan to maintain the system running successfully and safely.

Elevator upkeep personnel need to carry out regular examinations to determine signs of wear on vital elements such as ropes, sheaves, overview rails, and bearings. Additionally, keeping comprehensive upkeep documents can aid in tracking the wear patterns of elevator components over time, enabling for anticipating maintenance preparation. By closely keeping track of wear and tear, upkeep teams can attend to concerns proactively before they intensify into pricey repair work or unforeseen downtime, guaranteeing sites the secure and efficient operation of the lift system.

Comments on “How Lift Maintenance London Stands Out Amongst Local Lift Repair Companies”